Drawing Machine

We may Supply Al, Alloy, Cooper drawing line, machine, spare parts and agent material.

1. AL/Alloy Drawing Line

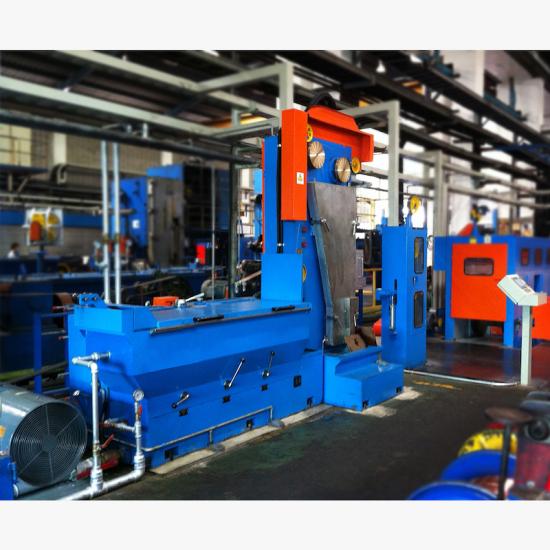

(1) High-Speed Individual Drive Al/Alloy Wire Drawing Machine LFD-560/450

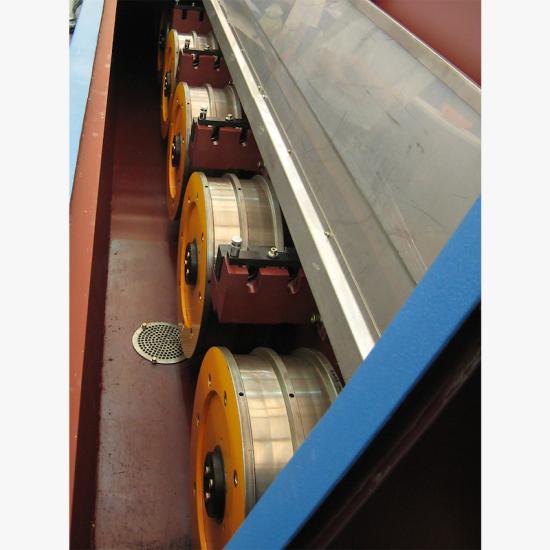

S-LFD-450/11 high-speed single-drive aluminum wire drawing machine is to make Φ9.5mm ordinary aluminum rod into Φ2.1mm-Φ4.5mm single aluminum wire. The wire drawing drum is arranged in a row for continuous drawing,the wire drawing host adopts single-drive full frequency conversion motor control; the energy saving effect is obvious; the mechanical and electrical speeds are balanced and the operation is convenient, and the fast die change is realized. This machine has the advantages of simple and convenient operation, high production efficiency, and good quality of finished products.Wire Drawing Machine with Individual Drive main body is welded from high-strength metal steel plate and finished by tempering and aging treatment. Guaranteed to be absolutely stable and easy to install!The front end of the main stand has a wire drawing wheel, by a drive system for the motor, reducer and guard.Drum wheel The fixed speed wheel is inlaid structure, the surface of the wide drum rim is sprayed with tungsten carbide, and the double-cone structure is used on both sides. When the surface is worn, only the drum ring needs to be replaced.Each of drawing drums is driven by a separate AC variable frequency motor through a reducer. The motor and the gear box are connected by a coupling. Control unified by PLC, can realize mode-hopping operation, and stop idle drums when drawing large-size wire, energy-saving and efficient.

(2) Al/Alloy Wire Drawing Machine with Individual Drive Type LFD-450/11

We are presenting precision Wire Drawing Machine that is developed for automatic annealing controls with lubricant enforced transmission gears and bearings. These are provided with dual spoolers and stainless steel covers for safety. It offers seamless control of spool wire tension with dancer attachment. We use the finest grades of metal alloys and other basic components to manufacture this under rigid standards of quality.

(3) Al/Alloy Wire Drawing Machine Type LHD-450

LHD-450/13 high-speed aluminum wire drawing machine is used to draw Φ9.5mm ordinary aluminum rods into Φ2.3 (1.8) mm-Φ4.5mm single aluminum wire. The wire drawing drum adopts a row arrangement, continuous drawing, balanced matching of mechanical and electrical speed, convenient operation, realizing quick die change, non-stop double reel automatic capture reel change and take-up, humanized design. This machine has the advantages of simple operation, convenience, high production efficiency, and good quality of finished products.The set of wire drawing machine is a ideal equipment drawing aluminum, and alloy wire. This machine is widly use for drawing wire in the factories such as wire steel factory, metal mesh factory, nail making factory etc.It used for drawing electrical Aluminium or Aluminium Alloy rod from 9.50mm to 1.80-4.50mm.

(4) Aluminum Rod Rewinder Type FLP-1400

The aluminum rod rewinding machines mainly used to rewind the ø9.5mm electrical aluminum rod. It rewinds the framed electrical aluminum rods which are produced in continuous casting and rolling process into dense arrangement of ø600×ø1400×ø 900 in bundle to easy for long-distance transportation.

2. Copper Drawing Line

(1) 8-Line Wire Copper Drawing Machine Type 21M-8/2500-8/630

Our multi-wire drawing machine was designed to greatly increase production capacity compared to standard drawing equipment. The drawing line can draw up to 8 pcs copper wires simultaneously. This efficiency increase is incluable to high capacity wire producers.There are 3 rows of Drawing Cones horizontally arranged in the drawing cabinet. There is a capstan at the output of drawing cabinet and it also works as a meter counter wheel. All of the Drawing Cones are treated the ceramic coating on the surface for the purpose of wear resistance. We design the control system with PLC + HMI that makes the whole system (Multiple Wires Drawing Machine + Annealing Machine + Take-up) work with the line speed in synchronization.

(2) Two-line Wire Drawing Machine Type DDL-450/13

wire drawing machine can be used in drawing metal wires made of aluminum, copper, etc. Upon operating, it can complete the drawing procedures with machine set according to the specifications at once, from feeding to finished product. The speed of the rear roll is increasing in sequence along with the thinning and lengthening of the wire rods. It is widely applied to the manufacturing of standard parts (e.g. welding rod, wire nail, screw, etc), lead, wire rope, spring etc.The machine has complete electrical system, perfect protection system and tap water seal cooling system, featured by easy combination, high productivity and convenient operation and management.

(3) Copper Wire Drawing Machine Type LHD-450

This Copper Wire Drawing Machine is used to draw copper rod in diameter of 8mm to copper wire in diameter of 1.35mm-4.0mm. Drawing capstan adopts linear horizontal arrangement, with continuous drawing and continuous annealing. Machine speed matches with the electrical speed, which achieves quick die changing and automatic bobbin shift without pause. This machine takes advantage of easy operation, high production efficiency and high product quality.

Extensively used for providing copper wire to make barbed wire, wire mesh and many more, this technologically advanced Copper Wire Drawing Machine is widely demanded amongst clients for its hassle free operation. This machine is manufactured using supreme grade components with the utilization of ultra-modern technology in tune with defined industry standards. Further, this Ultrafine copper wire drwaing machine is available in numerous technical specifications as per the varied needs of the clients at a competitive price. We are professional copper wire drawing machine manufacturers.

This Copper Rod Middle Drawing Machine is special for copper wire 0.4-1.2mm. Finished wire is wound by the 630 single or dual bobbin automatic change take-up machine. Power Transmitted by high accuracy bevel gears which are driven by AC two motors, lower noise, easier maintenance and reliable quality; To draw 17 copper wires at the same time, which will improve the quality ,meanwhile, it reduce the power consumption and reduce labor cost significantly. Two types annealing part are available.

(5) Compact Coiler Type JSM-1000

The JMS-1000 compact wire take-up machine is a compact high-speed wire take-up equipment, which is suitable for the finished copper flexible wire, soft and hard aluminum wire and coated finished wire after continuous annealing. The independent take-up system can be used with any brand of continuous annealing production line. The main machine of the take-up machine is driven by a 45KW DC motor and a high-speed imported V-belt drive. The cable is driven by a precision ball screw, and the servo AC motor drives the cable device to reverse and reverse on the linear guide. Through automatic tracking and adjustment of the row pitch, the wire stroke is adjusted by using a micro motor to drive the screw to change the distance of the stroke switch. The clamping spool adopts full hydraulic control, which is safe and reliable; the brake is an air hydraulic disc brake. The control panel of the take-up machine adopts a touch screen operation mode, and is also equipped with a separate emergency stop switch. The safety protection switch and brake system on the protective door can be connected with the emergency stop system of its supporting equipment to ensure the safety of the production process. The take-up spool adopts the expansion screw fastening structure, and the installation and disassembly with pneumatic special tools is simple and fast. The wire reel is hoisted with an expansion jack telescopic structure, which is safe and reliable for hoisting. The operation of the whole machine is simple and convenient.